Wood Plastic Composite decking has revolutionized outdoor construction by combining the natural appeal of wood with the durability of synthetic materials. As demand for sustainable and low-maintenance outdoor solutions grows, understanding the quality standards that govern WPC decking production becomes crucial for manufacturers, contractors, and property owners alike. These standards ensure that products meet rigorous performance criteria while delivering long-term value and safety for residential and commercial applications.

The quality control framework for WPC decking encompasses multiple dimensions, from raw material selection to final product testing. Manufacturers must navigate complex regulatory requirements while maintaining consistent production standards that deliver reliable performance across diverse environmental conditions. This comprehensive approach to quality assurance protects consumers and supports the continued growth of the composite decking industry through enhanced product credibility.

International Standards Governing WPC Decking Manufacturing

ASTM Standards for Composite Decking

The American Society for Testing and Materials establishes critical benchmarks for WPC decking performance through comprehensive testing protocols. ASTM D7032 provides the standard specification for establishing performance ratings for wood-plastic composite deck boards, addressing key factors including structural adequacy, durability, and maintenance requirements. This standard evaluates load-bearing capacity, deflection limits, and long-term structural integrity under various loading conditions.

ASTM testing methodologies also encompass weathering resistance, measuring how WPC decking responds to ultraviolet exposure, temperature fluctuations, and moisture cycling. These accelerated aging tests simulate years of outdoor exposure in controlled laboratory conditions, providing reliable data on color stability, surface integrity, and dimensional stability. Manufacturers use these test results to validate product warranties and establish performance expectations for different climate zones.

Additional ASTM standards address specific performance characteristics such as slip resistance, fire behavior, and fastener withdrawal strength. These comprehensive testing protocols ensure that WPC decking products meet minimum safety requirements while providing consistent performance data for comparative evaluation across different manufacturers and product lines.

European Standards and CE Marking Requirements

European markets require WPC decking products to comply with EN standards and obtain CE marking certification before market entry. EN 15534 series standards specifically address wood-plastic composites, establishing requirements for classification, specification, and marking of WPC products used in construction applications. These standards emphasize environmental sustainability, mechanical properties, and long-term durability under European climatic conditions.

The CE marking process requires comprehensive documentation of manufacturing processes, quality control procedures, and product performance data. Manufacturers must maintain detailed records of raw material sourcing, production parameters, and finished product testing to demonstrate compliance with applicable European regulations. This documentation serves as evidence of conformity with essential health, safety, and environmental protection requirements.

European standards also address environmental impact considerations, including recycled content requirements, formaldehyde emissions, and end-of-life recyclability. These sustainability-focused requirements align with broader European Union policies promoting circular economy principles and reduced environmental impact from construction materials. Compliance with these standards often requires third-party certification and ongoing surveillance audits.

Material Composition and Quality Control

Raw Material Specifications and Sourcing

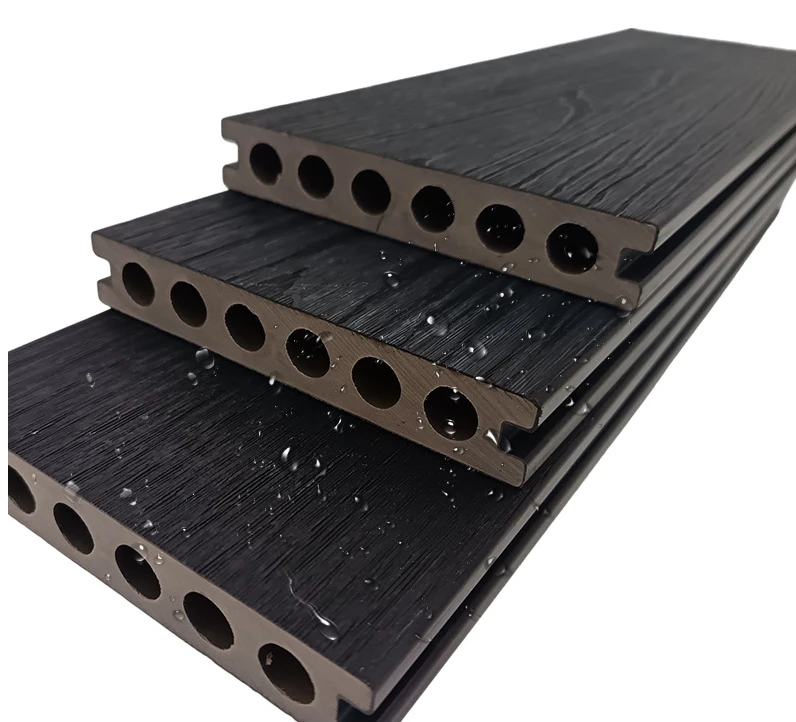

High-quality WPC decking begins with carefully selected raw materials that meet specific performance and sustainability criteria. Wood fiber components typically consist of recycled wood waste, sawdust, or wood flour derived from sustainably managed forests. The particle size distribution, moisture content, and chemical composition of wood components significantly impact the final product's mechanical properties and dimensional stability.

Polymer matrices in premium WPC decking products utilize high-grade polyethylene, polypropylene, or PVC resins that provide excellent weather resistance and structural integrity. Virgin polymer content ratios, melt flow characteristics, and chemical compatibility with additives require precise control to achieve consistent processing conditions and optimal product performance. Quality manufacturers implement rigorous incoming material inspection protocols to verify compliance with established specifications.

Additive packages including UV stabilizers, colorants, coupling agents, and processing aids must meet strict purity and performance standards. These specialized chemicals enhance product durability, appearance retention, and manufacturing processability while maintaining environmental safety requirements. Proper storage, handling, and mixing procedures for these sensitive additives ensure consistent product quality and prevent contamination or degradation during production.

Manufacturing Process Controls

Advanced WPC decking production facilities implement sophisticated process monitoring systems to maintain consistent quality throughout manufacturing operations. Temperature control during compounding and extrusion processes affects material homogeneity, surface finish quality, and dimensional accuracy. Automated monitoring systems track critical parameters including melt temperature, pressure profiles, and cooling rates to ensure optimal processing conditions.

Extrusion die design and maintenance significantly influence product quality, particularly surface texture, dimensional tolerances, and internal structure integrity. Regular die inspection, cleaning, and calibration procedures prevent defects such as surface irregularities, dimensional variations, or internal voids that could compromise product performance. Quality control technicians monitor extruded profiles continuously for visual defects, dimensional compliance, and surface quality.

Post-extrusion processes including cooling, sizing, cutting, and packaging require careful control to preserve product integrity and appearance. Controlled cooling rates prevent internal stresses that could lead to warping or dimensional instability over time. Automated cutting systems ensure precise length tolerances while minimizing end defects that could affect installation quality or aesthetic appearance.

Performance Testing and Validation

Structural Load Testing Protocols

Comprehensive structural testing validates WPC decking load-bearing capacity under various loading scenarios encountered in real-world applications. Static load testing evaluates maximum load capacity, deflection characteristics, and failure modes under concentrated and distributed loading conditions. These tests establish safe working loads and deflection limits that guide span recommendations and structural design requirements for different installation configurations.

Dynamic loading tests simulate repetitive foot traffic, furniture movement, and other cyclic loading conditions that WPC decking experiences during normal use. Fatigue testing protocols apply millions of load cycles to evaluate long-term structural integrity and identify potential failure modes that might develop over extended service periods. Results from these tests inform product warranties and maintenance recommendations for optimal long-term performance.

Impact resistance testing measures WPC decking ability to withstand sudden loads from falling objects, hail, or other impact events without suffering permanent damage. These tests evaluate both surface damage resistance and underlying structural integrity to ensure products maintain safety and appearance standards throughout their service life. Impact test results help architects and contractors select appropriate products for specific environmental conditions and usage requirements.

Environmental Durability Assessment

Accelerated weathering tests expose WPC decking samples to intensified UV radiation, temperature cycling, and moisture exposure to simulate years of outdoor service in compressed timeframes. These controlled laboratory conditions allow manufacturers to evaluate color stability, surface degradation, and mechanical property retention under various climatic conditions. Standardized weathering protocols ensure consistent and comparable results across different testing facilities and product lines.

Freeze-thaw cycling tests evaluate WPC decking performance in regions experiencing seasonal temperature variations below freezing. These tests measure dimensional changes, surface integrity, and mechanical property retention after repeated freeze-thaw cycles. Results help manufacturers optimize material formulations for cold climate applications and establish appropriate installation guidelines for temperature-sensitive regions.

Biological resistance testing evaluates WPC decking resistance to fungal decay, insect damage, and other biological deterioration mechanisms. Laboratory tests expose samples to various wood-destroying organisms under controlled conditions to measure weight loss, structural integrity, and visual appearance changes. These tests are particularly important for establishing product suitability in high-moisture environments where biological activity could compromise long-term performance.

Quality Assurance Systems and Certification

ISO Quality Management Implementation

Leading WPC decking manufacturers implement ISO 9001 quality management systems to ensure consistent product quality and continuous improvement processes. These comprehensive quality frameworks establish documented procedures for all aspects of production, from raw material procurement through final product delivery. Regular internal audits and management reviews ensure ongoing compliance with established quality objectives and customer requirements.

ISO 14001 environmental management systems complement quality assurance efforts by addressing environmental impacts throughout the manufacturing process. These systems emphasize waste reduction, energy efficiency, and sustainable resource utilization while maintaining product quality standards. Environmental management integration supports corporate sustainability goals while meeting increasingly stringent environmental regulations and customer expectations.

Statistical process control methods track key quality metrics throughout production operations, enabling early detection of process variations that could affect product quality. Control charts, capability studies, and trend analysis help production teams maintain optimal process conditions while identifying opportunities for quality improvements. These data-driven approaches support continuous improvement initiatives and customer satisfaction objectives.

Third-Party Certification Programs

Independent certification bodies provide objective verification of WPC decking quality and performance through comprehensive testing and facility audits. These certification programs evaluate products against established industry standards while verifying manufacturing quality systems and ongoing compliance monitoring. Third-party certifications provide additional credibility for product claims and support marketing efforts in competitive markets.

Green building certification programs such as LEED and BREEAM recognize high-performance WPC decking products that meet sustainability criteria including recycled content, low emissions, and end-of-life recyclability. These certifications support architects and builders seeking environmentally responsible building materials while potentially qualifying projects for green building incentives and recognition programs.

Product liability insurance requirements often specify minimum certification levels and ongoing quality assurance documentation for WPC decking applications. Manufacturers maintaining comprehensive certification portfolios demonstrate commitment to product quality and safety while providing additional protection for customers, contractors, and end users. These certifications also facilitate international market access by meeting diverse regulatory requirements across different jurisdictions.

Installation and Maintenance Quality Standards

Professional Installation Guidelines

Proper installation practices are essential for realizing the full performance potential of high-quality WPC decking systems. Manufacturer installation guidelines specify appropriate fastener types, spacing requirements, and substructure specifications to ensure optimal structural performance and appearance retention. These guidelines address thermal expansion considerations, drainage requirements, and ventilation needs specific to composite decking materials.

Certified installer training programs provide contractors with specialized knowledge of WPC decking installation techniques, quality control procedures, and troubleshooting methods. These programs ensure installations meet manufacturer specifications while providing warranty protection for property owners. Professional installation certification also supports contractor credibility and competitive positioning in the marketplace.

Quality control checklists and inspection protocols help installers verify compliance with manufacturer specifications throughout the installation process. These systematic approaches prevent common installation errors that could compromise product performance or appearance while ensuring projects meet established quality standards. Documentation of installation procedures supports warranty claims and provides valuable feedback for product development and installation guideline refinement.

Long-Term Performance Monitoring

Ongoing maintenance requirements for WPC decking products are minimal compared to traditional wood decking, but specific care procedures help maintain optimal appearance and performance throughout the product lifecycle. Regular cleaning protocols remove surface contaminants that could promote biological growth or surface staining while preserving the original appearance and texture characteristics.

Periodic inspection procedures identify potential issues such as fastener loosening, surface wear patterns, or drainage problems before they compromise overall system performance. Early detection and correction of minor issues prevent more significant problems while extending product service life and maintaining safety standards. Inspection documentation supports warranty compliance and provides valuable performance data for future product improvements.

Performance tracking systems monitor WPC decking installations over time to validate laboratory test predictions and identify opportunities for product or installation improvements. Field performance data helps manufacturers refine quality standards, update installation guidelines, and develop enhanced product formulations that address real-world performance challenges. This feedback loop ensures continuous improvement in product quality and customer satisfaction.

FAQ

What are the most important quality certifications to look for in WPC decking?

The most critical certifications for WPC decking include ASTM D7032 compliance for structural performance, ICC-ES evaluation reports for building code compliance, and third-party certifications from recognized testing laboratories. Environmental certifications such as GreenGuard or Forest Stewardship Council recognition demonstrate commitment to sustainability and low emissions. Additionally, ISO 9001 certification indicates robust quality management systems, while regional certifications like CE marking are essential for European markets.

How do quality standards differ between residential and commercial WPC decking applications?

Commercial WPC decking applications typically require higher performance standards including increased load-bearing capacity, enhanced fire resistance, and more stringent slip resistance requirements. Commercial installations often mandate compliance with Americans with Disabilities Act accessibility standards and may require specialized testing for high-traffic applications. Additionally, commercial projects frequently specify extended warranty periods, third-party performance verification, and enhanced maintenance documentation compared to residential applications.

What quality control measures should installers implement during WPC decking installation?

Professional installers should verify product authenticity through manufacturer identification codes, inspect materials for shipping damage or defects before installation, and document compliance with manufacturer spacing and fastening requirements. Quality control measures include verifying proper substructure preparation, maintaining specified expansion gaps, ensuring adequate drainage and ventilation, and conducting final inspections using manufacturer-provided checklists. Documentation of installation procedures and any deviations from specifications supports warranty coverage and provides valuable performance feedback.

How do environmental conditions affect WPC decking quality requirements?

Environmental conditions significantly influence WPC decking quality requirements, with coastal installations requiring enhanced corrosion resistance and UV stabilization due to salt exposure and intense sunlight. Cold climate applications need improved freeze-thaw resistance and thermal stability, while hot climates require enhanced heat resistance and dimensional stability. High-moisture environments may require additional anti-microbial treatments and improved drainage characteristics. Manufacturers often provide climate-specific product recommendations and modified installation guidelines to address these environmental challenges.

Table of Contents

- International Standards Governing WPC Decking Manufacturing

- Material Composition and Quality Control

- Performance Testing and Validation

- Quality Assurance Systems and Certification

- Installation and Maintenance Quality Standards

-

FAQ

- What are the most important quality certifications to look for in WPC decking?

- How do quality standards differ between residential and commercial WPC decking applications?

- What quality control measures should installers implement during WPC decking installation?

- How do environmental conditions affect WPC decking quality requirements?