Modern outdoor construction projects increasingly rely on innovative materials that combine durability, aesthetics, and environmental responsibility. WPC decking has emerged as a revolutionary solution that addresses the limitations of traditional wood while providing superior performance in challenging outdoor environments. This composite material represents a significant advancement in construction technology, offering builders and homeowners a versatile option that withstands weather extremes, requires minimal maintenance, and delivers long-term value. The widespread adoption of WPC decking across residential and commercial projects demonstrates its effectiveness in meeting contemporary construction demands while supporting sustainable building practices.

Understanding WPC Decking Composition and Manufacturing

Material Components and Structure

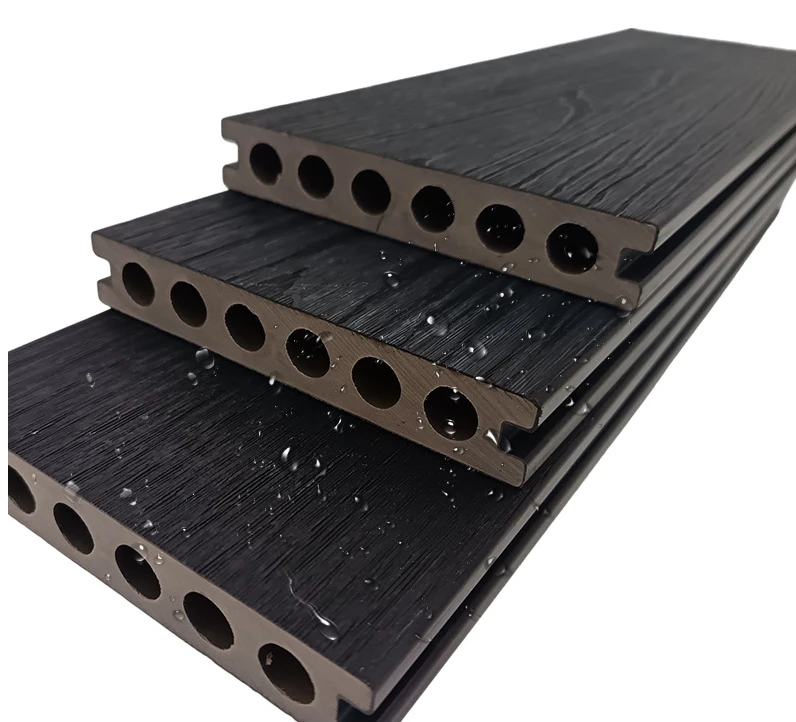

WPC decking consists of a carefully engineered blend of wood fibers, thermoplastic polymers, and specialized additives that create a composite material superior to its individual components. The wood content typically ranges from 50 to 70 percent, providing natural aesthetics and structural properties, while the polymer component ensures water resistance and dimensional stability. Manufacturing processes involve precise temperature control and pressure application to achieve optimal fiber distribution and polymer bonding. This scientific approach to material composition results in WPC decking that exhibits consistent performance characteristics across different environmental conditions.

The manufacturing process begins with the careful selection and preparation of wood fibers, which are dried and sized to specific dimensions for optimal composite integration. Thermoplastic resins undergo similar preparation, with additives introduced to enhance UV resistance, color stability, and flame retardancy. Advanced extrusion techniques combine these materials under controlled conditions, creating profiles with consistent density and mechanical properties. Quality control measures throughout production ensure that each WPC decking board meets stringent performance standards for strength, durability, and appearance.

Advanced Additive Systems

Modern WPC decking incorporates sophisticated additive packages that significantly enhance performance characteristics beyond basic wood-polymer combinations. UV stabilizers prevent color degradation and material breakdown under intense sunlight exposure, while antioxidants protect against thermal degradation during temperature fluctuations. Coupling agents improve the interfacial bonding between wood fibers and polymer matrix, resulting in superior mechanical properties and moisture resistance. These additives work synergistically to create WPC decking systems that maintain structural integrity and aesthetic appeal throughout extended service life.

Specialized additives address specific performance requirements for different applications and environmental conditions. Anti-fungal agents prevent biological degradation, while flame retardants meet building code requirements for fire safety. Colorants and surface treatments provide diverse aesthetic options while maintaining fade resistance. The precise formulation of these additive systems allows manufacturers to customize WPC decking properties for specific market segments and geographic regions with varying climate conditions.

Superior Weather Resistance and Durability

Moisture and Water Damage Prevention

WPC decking demonstrates exceptional resistance to moisture-related damage that commonly affects traditional wood decking systems. The polymer encapsulation of wood fibers creates a barrier that prevents water penetration while allowing controlled moisture exchange to maintain dimensional stability. This unique characteristic eliminates common problems such as warping, splitting, and rotting that plague conventional wood decking installations. Field testing under extreme moisture conditions has validated the superior performance of WPC decking in humid climates and areas with frequent precipitation.

The closed-cell structure of quality WPC decking systems provides additional protection against freeze-thaw cycles that can cause significant damage to traditional materials. Water absorption rates typically remain below 2 percent by weight, compared to 15-20 percent for untreated wood. This low absorption characteristic prevents ice expansion damage and reduces maintenance requirements in cold climate applications. WPC decking installations maintain structural integrity and appearance even after years of exposure to challenging weather conditions.

UV Stability and Color Retention

Advanced UV stabilization systems in modern WPC decking provide superior color retention compared to traditional wood materials that fade and gray under prolonged sun exposure. Specialized additives absorb harmful UV radiation before it can break down polymer chains or degrade organic colorants. Laboratory accelerated aging tests demonstrate that quality WPC decking maintains color consistency for decades under normal outdoor exposure conditions. This performance characteristic eliminates the need for frequent refinishing and reduces long-term maintenance costs significantly.

The UV resistance of WPC decking extends beyond color preservation to include structural stability under intense solar radiation. Polymer degradation under UV exposure can lead to surface chalking and mechanical property loss in inferior products. Premium WPC decking formulations incorporate multiple UV stabilization mechanisms that protect both surface appearance and structural integrity. This comprehensive approach ensures that WPC decking maintains its intended performance characteristics throughout its design service life.

Environmental Benefits and Sustainability

Recycled Content and Resource Conservation

WPC decking production utilizes significant quantities of recycled materials, including post-consumer plastic waste and wood processing byproducts that would otherwise require disposal. This resource recovery approach diverts waste from landfills while creating valuable construction materials with superior performance characteristics. The incorporation of recycled content typically ranges from 30 to 95 percent of total material volume, depending on manufacturer specifications and product lines. This circular economy approach reduces demand for virgin materials while addressing waste management challenges.

Manufacturing processes for WPC decking optimize material utilization through efficient production techniques that minimize waste generation. Scrap materials generated during production can be reprocessed and incorporated into new products, creating closed-loop manufacturing systems. This approach contrasts favorably with traditional wood harvesting and processing, which generates substantial waste and requires continuous depletion of forest resources. The environmental benefits of WPC decking extend throughout the product lifecycle, from raw material sourcing through end-of-life recycling.

Reduced Chemical Treatment Requirements

Unlike pressure-treated lumber that requires toxic chemical preservatives to achieve outdoor durability, WPC decking achieves superior performance through material engineering rather than chemical treatments. This approach eliminates concerns about chemical leaching into soil and groundwater that can occur with treated wood installations. The inherent durability of WPC decking materials eliminates the need for periodic chemical reapplication, reducing environmental exposure and maintenance costs over the product lifecycle.

The absence of chemical preservatives in WPC decking also improves indoor air quality and reduces health concerns associated with volatile organic compound emissions. Traditional wood stains, sealers, and preservatives contribute to air pollution and may pose health risks during application and curing. WPC decking installations can proceed without these chemical treatments while achieving superior long-term performance. This characteristic makes WPC decking particularly suitable for residential applications where environmental health considerations are paramount.

Installation Efficiency and Construction Advantages

Simplified Installation Procedures

WPC decking systems feature engineering improvements that streamline installation procedures while reducing labor costs and construction time. Consistent dimensional stability eliminates the need for extensive material sorting and selection that characterizes wood decking installations. Standardized profiles and connection systems ensure predictable fit and finish results regardless of installer experience level. These characteristics make WPC decking particularly attractive for commercial construction projects with tight scheduling constraints and quality requirements.

Advanced fastening systems designed specifically for WPC decking applications provide secure attachment while accommodating thermal expansion and contraction. Hidden fastening options eliminate visible hardware while maintaining structural integrity and aesthetic appeal. Installation tools and techniques developed for WPC decking reduce the skill level required for professional-quality results. These installation advantages translate directly into reduced construction costs and improved project profitability for contractors and builders.

Structural Performance and Load Capacity

Engineering properties of WPC decking systems meet or exceed structural requirements for residential and commercial decking applications. Flexural strength, impact resistance, and load-bearing capacity have been validated through extensive testing protocols that simulate real-world loading conditions. The consistent material properties of manufactured WPC decking eliminate the variability in strength characteristics that can affect traditional wood installations. This predictability allows engineers to design structures with confidence in long-term performance.

Thermal expansion characteristics of WPC decking require consideration during design and installation to prevent buckling and gap formation. Modern WPC decking formulations minimize thermal movement through material engineering and additive systems. Installation guidelines specify appropriate expansion joint spacing and fastening techniques to accommodate thermal cycling while maintaining structural integrity. Proper installation of WPC decking systems results in stable, long-lasting outdoor structures that require minimal ongoing maintenance.

Cost-Effectiveness and Long-Term Value

Lifecycle Cost Analysis

Comprehensive cost analysis reveals that WPC decking provides superior value compared to traditional materials when evaluated over typical service life periods. Initial material costs for WPC decking may exceed those of pressure-treated lumber, but reduced maintenance requirements and extended service life result in lower total ownership costs. Regular staining, sealing, and repair requirements for wood decking create ongoing expenses that accumulate significantly over time. WPC decking eliminates most of these maintenance activities while providing consistent appearance and performance.

Labor costs for maintenance and replacement activities represent significant hidden expenses in traditional decking systems. WPC decking reduces these costs through improved durability and reduced maintenance requirements. Professional cost analyses typically show payback periods of 5-7 years for WPC decking installations, after which the cost advantages compound annually. These financial benefits make WPC decking particularly attractive for commercial applications where maintenance costs and downtime have significant business impacts.

Property Value Enhancement

WPC decking installations contribute positively to property values through improved aesthetics, reduced maintenance requirements, and enhanced functionality. Real estate professionals report that quality decking systems can provide returns on investment exceeding 70 percent of installation costs. The consistent appearance and low maintenance characteristics of WPC decking appeal to potential buyers who recognize the long-term value proposition. This market recognition makes WPC decking a sound investment for both residential and commercial property owners.

The aesthetic versatility of WPC decking allows design flexibility that enhances architectural compatibility and curb appeal. Available colors, textures, and profiles provide options suitable for diverse architectural styles and personal preferences. This design flexibility, combined with superior performance characteristics, positions WPC decking as a premium building material that commands market recognition and value retention. Property owners benefit from both immediate aesthetic improvements and long-term value preservation.

Market Trends and Industry Adoption

Construction Industry Acceptance

Professional contractors and builders increasingly specify WPC decking for both residential and commercial projects based on demonstrated performance advantages and client satisfaction. Industry surveys indicate that WPC decking adoption rates continue to grow as awareness of benefits increases and product quality improvements address earlier concerns. Major construction companies now include WPC decking as standard options in their material specifications, reflecting confidence in long-term performance and customer acceptance.

Building code acceptance and professional certification programs support the growing adoption of WPC decking in commercial construction applications. Testing and certification by recognized standards organizations provide assurance of structural performance and safety characteristics. This professional validation enables architects and engineers to specify WPC decking with confidence in code compliance and liability protection. The resulting market acceptance accelerates adoption across diverse construction segments.

Technological Advancement and Innovation

Ongoing research and development activities continue to improve WPC decking performance characteristics while reducing production costs and environmental impacts. Advanced manufacturing techniques enable production of profiles with enhanced structural properties and surface characteristics. New additive systems provide improved weather resistance and aesthetic options. These technological improvements maintain the competitive advantages of WPC decking while addressing emerging market requirements and environmental regulations.

Innovation in WPC decking extends to installation systems, maintenance products, and complementary accessories that enhance overall system performance. Specialized fasteners, railings, and trim components create integrated systems that simplify specification and installation while ensuring consistent quality and appearance. This systems approach provides additional value to specifiers and installers while supporting continued market growth and acceptance.

FAQ

How long does WPC decking typically last compared to traditional wood decking?

WPC decking typically provides 25-30 years of service life with minimal maintenance, compared to 10-15 years for pressure-treated wood decking that requires regular maintenance. The polymer protection and engineered composition of WPC decking eliminate common failure modes such as rotting, warping, and insect damage that limit wood decking lifespan. This extended service life, combined with reduced maintenance requirements, provides significant long-term value advantages for property owners.

Does WPC decking require special installation techniques or tools?

WPC decking can be installed using standard carpentry tools and techniques, though specific fastening systems and expansion joint requirements should be followed for optimal performance. Hidden fastening systems designed for WPC decking provide superior aesthetics and structural performance compared to traditional face screwing methods. Installation guidelines specify proper spacing, ventilation, and thermal expansion accommodation to ensure long-term structural integrity and appearance retention.

Can WPC decking be recycled at the end of its service life?

Yes, WPC decking materials can be recycled through specialized processing facilities that separate and recover both the wood fiber and thermoplastic components. The thermoplastic content allows reprocessing into new WPC products or other plastic applications, while wood fibers can be utilized in various manufactured wood products. This recyclability supports circular economy principles and reduces environmental impact throughout the product lifecycle.

How does WPC decking perform in extreme temperature conditions?

WPC decking maintains structural integrity and dimensional stability across wide temperature ranges, from -40°F to 160°F in typical applications. Thermal expansion characteristics require proper installation techniques to accommodate movement, but the material itself does not suffer degradation from temperature cycling. Advanced formulations include additives that enhance performance in specific climate conditions, making WPC decking suitable for diverse geographic regions and weather patterns.