बाहरी स्थानों के लिए सही फ़्लोरिंग सामग्री का चयन करने के लिए टिकाऊपन, सौंदर्य और दीर्घकालिक प्रदर्शन पर सावधानीपूर्वक विचार करने की आवश्यकता होती है। लैंडस्केपिंग परियोजनाओं और सार्वजनिक क्षेत्र विकास के लिए WPC डेकिंग एक प्रमुख समाधान के रूप में उभरी है, जो पारंपरिक लकड़ी की प्राकृतिक उपस्थिति को बनाए रखते हुए मौसमी परिस्थितियों के प्रति उत्कृष्ट प्रतिरोध प्रदान करती है। यह व्यापक मार्गदर्शिका WPC डेकिंग चयन को प्रभावित करने वाले आवश्यक कारकों का पता लगाती है, जो परियोजना प्रबंधकों और संपत्ति विकासकर्ताओं को अपने बाहरी स्थापना के लिए जानकारीपूर्ण निर्णय लेने में सहायता करती है।

वुड प्लास्टिक कंपोजिट तकनीक प्राकृतिक लकड़ी की सौंदर्य आकर्षकता के साथ-साथ बेहतर प्रदर्शन विशेषताओं को जोड़कर आउटडोर फर्श सामग्री में एक महत्वपूर्ण प्रगति का प्रतिनिधित्व करती है। आधुनिक WPC डेकिंग प्रणाली व्यावसायिक और आवासीय अनुप्रयोगों के लिए असाधारण मूल्य प्रदान करती है, जो विभिन्न पर्यावरणीय परिस्थितियों में समान गुणवत्ता प्रदान करती है। WPC डेकिंग के संघटन और निर्माण प्रक्रियाओं को समझने से विशिष्ट परियोजना आवश्यकताओं के लिए बेहतर सामग्री चयन संभव होता है।

WPC डेकिंग संरचना और लाभ की समझ

सामग्री की संरचना और निर्माण प्रक्रिया

डब्ल्यूपीसी डेकिंग में सावधानीपूर्वक संतुलित लकड़ी के तंतु और पॉलिमर घटक शामिल होते हैं, जो एक संकर सामग्री बनाते हैं जो कई प्रदर्शन श्रेणियों में पारंपरिक विकल्पों से बेहतर प्रदर्शन करती है। निर्माण प्रक्रिया में प्रत्येक बोर्ड में सुसंगत घनत्व और संरचनात्मक बनावट सुनिश्चित करने के लिए सटीक तापमान नियंत्रण और दबाव लगाना शामिल है। उच्च-गुणवत्ता वाली डब्ल्यूपीसी डेकिंग में उन्नत योज्य शामिल होते हैं जो पराबैंगनी प्रतिरोध, रंग स्थिरता और नमी सुरक्षा में सुधार करते हैं, जिससे पारंपरिक लकड़ी के उत्पादों की तुलना में सेवा जीवन में महत्वपूर्ण वृद्धि होती है।

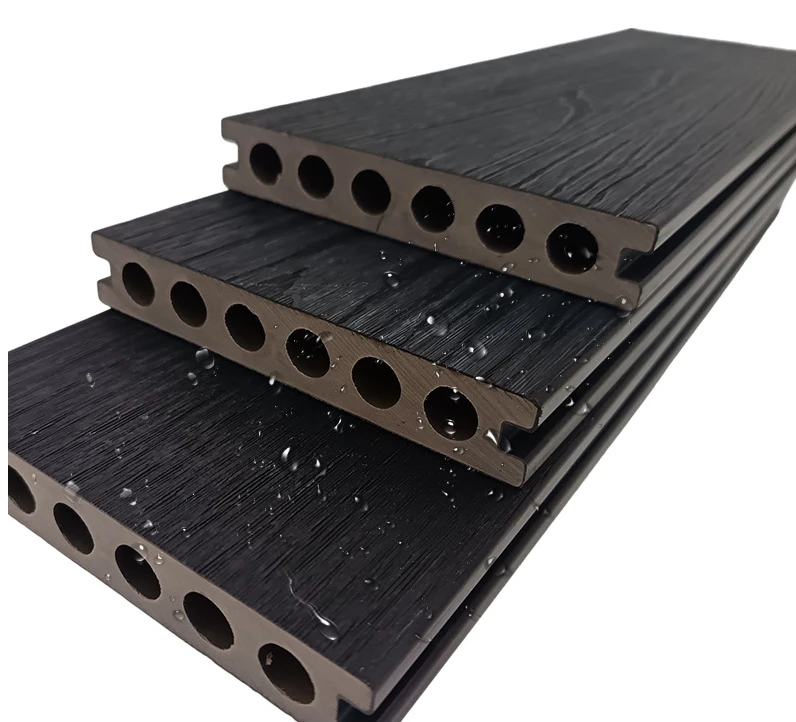

डेकिंग उत्पादन में WPC में उपयोग की जाने वाली एक्सट्रूज़न प्रक्रिया जटिल प्रोफ़ाइल डिज़ाइन की अनुमति देती है, जो कार्यक्षमता और सौंदर्य आकर्षण दोनों में सुधार करती है। खोखले कोर डिज़ाइन सामग्री के वजन को कम करते हुए संरचनात्मक शक्ति बनाए रखते हैं, जिससे स्थापना आसान हो जाती है और परिवहन लागत में कमी आती है। निर्माण के दौरान सतह पर बनाए गए टेक्सचर फिसलन रोकथाम में वृद्धि और प्रामाणिक लकड़ी के दाने के पैटर्न प्रदान करते हैं, जो सुरक्षा आवश्यकताओं और डिज़ाइन वरीयताओं दोनों को पूरा करते हैं।

पारंपरिक सामग्री की तुलना में प्रदर्शन लाभ

प्राकृतिक लकड़ी की तुलना में WPC डेकिंग आकार में उत्कृष्ट स्थिरता दर्शाती है, जिससे मुड़ने, फटने और अंतराल बनने के कारण होने वाले विस्तार और संकुचन के चक्र कम हो जाते हैं। यह स्थिरता विशेष रूप से सार्वजनिक क्षेत्रों में मूल्यवान साबित होती है, जहाँ निरंतर सतह की स्थिति उपयोगकर्ता सुरक्षा सुनिश्चित करती है और रखरखाव हस्तक्षेप कम होता है। संयुक्त संरचना कीट नुकसान, सड़ांध और फंगल वृद्धि का प्रतिरोध करती है, जो बाहरी वातावरण में पारंपरिक लकड़ी के डेकिंग के साथ जुड़ी सामान्य समस्याओं को खत्म करती है।

उत्पाद जीवनकाल के दौरान WPC डेकिंग प्रणालियों के लिए रखरखाव आवश्यकताएँ न्यूनतम बनी रहती हैं, जिसमें अनुकूल दिखावट और प्रदर्शन बनाए रखने के लिए केवल आवधिक सफाई की आवश्यकता होती है। पारंपरिक लकड़ी के उत्पादों के विपरीत, जिन्हें नियमित रूप से रंगाई, सील करने या क्षतिग्रस्त बोर्डों के प्रतिस्थापन की आवश्यकता होती है, WPC डेकिंग लंबी अवधि तक अपना मूल रंग और बनावट बनाए रखती है। इस कम रखरखाव अनुसूची का अर्थ है स्थापना के जीवनकाल में महत्वपूर्ण लागत बचत, जिससे बजट-संज्ञान वाली परियोजनाओं के लिए WPC डेकिंग एक आर्थिक रूप से आकर्षक विकल्प बन जाती है।

विभिन्न अनुप्रयोगों के लिए महत्वपूर्ण चयन कारक

जलवायु पर विचार और पर्यावरणीय प्रतिरोध

जलवायु परिस्थितियाँ डब्ल्यूपीसी डेकिंग के प्रदर्शन को काफी हद तक प्रभावित करती हैं, जिसके कारण स्थानीय पर्यावरणीय कारकों के आधार पर सामग्री का सावधानीपूर्वक चयन करना आवश्यक होता है। उच्च तापमान वाले वातावरण में सतह के विरूपण और रंग फीकेपन से बचने के लिए ऊष्मा प्रतिरोध और तापीय प्रसार गुणों में सुधार वाले डब्ल्यूपीसी डेकिंग सूत्रीकरण की आवश्यकता होती है। तटीय स्थापनाओं के लिए संरचनात्मक अखंडता और सौंदर्य गुणवत्ता को समय के साथ बनाए रखने के लिए बढ़ी हुई नमकीन वायु प्रतिरोधकता और पराबैंगनी (यूवी) सुरक्षा वाले विशेष डब्ल्यूपीसी डेकिंग की आवश्यकता होती है।

आर्द्रता स्तर और मौसमी मौसम पैटर्न विभिन्न भौगोलिक क्षेत्रों के लिए डब्ल्यूपीसी डेकिंग के चयन को प्रभावित करते हैं। उच्च आर्द्रता या बार-बार वर्षा वाले क्षेत्रों को आर्द्रता प्रतिरोध और जल निकासी क्षमता में उत्कृष्ट डब्ल्यूपीसी डेकिंग से लाभ मिलता है। ठंडे जलवायु अनुप्रयोगों के लिए ऐसी डब्ल्यूपीसी डेकिंग सामग्री की आवश्यकता होती है जो निम्न तापमान पर लचीलापन और प्रभाव प्रतिरोध बनाए रखती हों, जिससे जमने-पिघलने के चक्र के दौरान दरारें और संरचनात्मक विफलता होने से रोका जा सके।

भार आवश्यकताएँ और संरचनात्मक विनिर्देश

सार्वजनिक क्षेत्र के अनुप्रयोगों में आवासीय स्थापनाओं की तुलना में अक्सर अधिक पैदल यातायात और भार आवश्यकताएं होती हैं, जिसके कारण संरचनात्मक गुणों में वृद्धि वाले WPC डेकिंग की आवश्यकता होती है। व्यावसायिक-ग्रेड WPC डेकिंग में सघन भार और बार-बार उपयोग के पैटर्न का समर्थन करने के लिए मजबूत कोर डिज़ाइन और बढ़ी हुई घनत्व शामिल होती है। मजबूत निष्कर्ष अंतराल और अधोसंरचना डिज़ाइन WPC डेकिंग के चयन की पूरकता करते हैं ताकि मांग वाली परिस्थितियों के तहत दीर्घकालिक प्रदर्शन सुनिश्चित किया जा सके।

पूल डेक, पथ और खुले मनोरंजन सुविधाओं जैसे विशेष अनुप्रयोगों की आवश्यकता होती है WPC डेकिंग फिसलन प्रतिरोध, रासायनिक प्रतिरोध और बढ़ी हुई टिकाऊपन रेटिंग सहित विशिष्ट प्रदर्शन विशेषताओं के साथ। चयन प्रक्रिया के दौरान इन आवश्यकताओं को समझने से प्रदर्शन संबंधी समस्याओं को रोका जा सकता है और प्रासंगिक भवन नियमों और सुरक्षा मानकों के साथ अनुपालन सुनिश्चित किया जा सकता है।

स्थापना विधियाँ और प्रणाली एकीकरण

फास्टनिंग प्रणाली और संयोजन विधियाँ

आधुनिक WPC डेकिंग प्रणालियों में छिपे हुए फास्टनर प्रणाली, पारंपरिक स्क्रू-डाउन विधियाँ और क्लिप-आधारित संयोजन प्रणालियों सहित कई स्थापना विधियाँ शामिल हैं। छिपे हुए फास्टनर प्रणाली सामग्री की प्राकृतिक गति की अनुमति देते हुए सतह की स्वच्छ उपस्थिति प्रदान करती हैं और थर्मल ब्रिजिंग को कम करती हैं। उपयुक्त फास्टनिंग विधियों के चयन WPC डेकिंग प्रोफ़ाइल डिज़ाइन, पर्यावरणीय स्थितियों और विशिष्ट अनुप्रयोग के लिए सौंदर्य आवश्यकताओं पर निर्भर करता है।

उचित फास्टनर का चयन दीर्घकालिक संयोजन अखंडता सुनिश्चित करता है और संक्षारण या यांत्रिक तनाव के कारण समय से पहले विफलता को रोकता है। बाहरी वातावरण में स्टेनलेस स्टील या विशेष रूप से लेपित फास्टनर संक्षारण का प्रतिरोध करते हैं और WPC डेकिंग स्थापना के लिए पर्याप्त धारण शक्ति प्रदान करते हैं। WPC डेकिंग सामग्री की थर्मल विस्तार विशेषताओं को ध्यान में रखते हुए स्थापना तकनीकों को तापमान में उतार-चढ़ाव के दौरान ऐंठन या अंतर के निर्माण को रोकने के लिए अनुकूलित करना चाहिए।

सबस्ट्रक्चर आवश्यकताएँ और फाउंडेशन डिज़ाइन

डब्ल्यूपीसी डेकिंग का प्रदर्शन उचित सबस्ट्रक्चर डिज़ाइन और स्थापना की गुणवत्ता पर भारी मात्रा में निर्भर करता है। डब्ल्यूपीसी डेकिंग के नीचे पर्याप्त वेंटिलेशन नमी के जमाव को रोकता है और स्थापना के आयुष्काल के दौरान इष्टतम तापीय प्रदर्शन सुनिश्चित करता है। डब्ल्यूपीसी डेकिंग की मोटाई और लोड आवश्यकताओं के आधार पर जॉइस्ट स्पेसिंग सिफारिशें भिन्न होती हैं, जहां उच्च यातायात वाले अनुप्रयोगों और पतले बोर्ड प्रोफाइल के लिए कम स्पेसिंग की आवश्यकता होती है।

फाउंडेशन डिज़ाइन पर विचार में जल निकासी प्रबंधन, फ्रॉस्ट सुरक्षा और भविष्य के रखरखाव गतिविधियों के लिए पहुंच शामिल है। उचित ढलान और जल निकासी प्रणाली पानी के जमाव को रोकती है जो डब्ल्यूपीसी डेकिंग के प्रदर्शन और सबस्ट्रक्चर की अखंडता को प्रभावित कर सकती है। इन डिज़ाइन तत्वों को डब्ल्यूपीसी डेकिंग चयन के साथ समन्वय की आवश्यकता होती है ताकि सुसंगतता और इष्टतम सिस्टम प्रदर्शन सुनिश्चित किया जा सके।

सौंदर्य विकल्प और डिज़ाइन एकीकरण

रंग चयन और सतह के टेक्सचर

समकालीन डब्ल्यूपीसी डेकिंग निर्माता विभिन्न वास्तुकला शैलियों और परिदृश्य डिज़ाइन के अनुरूप लाने के लिए विस्तृत रंग पैलेट और सतह बनावट विकल्प प्रदान करते हैं। रंग स्थिरता प्रौद्योगिकी यह सुनिश्चित करती है कि सेवा जीवन के दौरान डब्ल्यूपीसी डेकिंग अपनी मूल उपस्थिति बनाए रखे, जो अन्य बाहरी सामग्री में आम फीकापन और रंग बदलने के खिलाफ प्रतिरोध करती है। बहु-स्वर रंग भिन्नताएँ और वास्तविक लकड़ी के दाने के पैटर्न प्रामाणिक प्राकृतिक लकड़ी की उपस्थिति प्रदान करते हैं, जबकि उत्कृष्ट प्रदर्शन विशेषताएँ प्रदान करते हैं।

डब्ल्यूपीसी डेकिंग स्थापनाओं की सौंदर्य आकर्षण और कार्यात्मक प्रदर्शन दोनों को सतह बनावट चयन प्रभावित करता है। चिकनी सतहें आधुनिक वास्तुकला अनुप्रयोगों के लिए उपयुक्त समकालीन उपस्थिति प्रदान करती हैं, जबकि बनावट वाली सतहें सुरक्षा-महत्वपूर्ण क्षेत्रों के लिए बढ़ी हुई फिसलन प्रतिरोध प्रदान करती हैं। उभरे हुए लकड़ी के दाने के पैटर्न सौंदर्य प्रामाणिकता के साथ-साथ विभिन्न मौसम की स्थितियों के तहत कम चमक और सुधरी गतिशीलता सहित व्यावहारिक लाभों को भी जोड़ते हैं।

प्रोफ़ाइल विकल्प और आयामी प्रकल्पनाएँ

WPC डेकिंग प्रोफ़ाइल के चयन से बाहरी स्थानों की स्थापना विधियों और अंतिम रूप दोनों पर प्रभाव पड़ता है। ठोस प्रोफ़ाइल अधिकतम मजबूती और पारंपरिक लकड़ी की उपस्थिति प्रदान करते हैं, जबकि खोखले प्रोफ़ाइल सामग्री के भार को कम करते हैं और एकीकृत वायरिंग या ड्रेनेज प्रणालियों की अनुमति देते हैं। बोर्ड की चौड़ाई और मोटाई के विकल्प विभिन्न अनुप्रयोगों के लिए विशिष्ट संरचनात्मक और सौंदर्य आवश्यकताओं को पूरा करते हुए डिज़ाइन लचीलापन प्रदान करते हैं।

ग्रूव्ड, स्मूथ और बेवल्ड प्रोफ़ाइल सहित किनारे के उपचार विकल्प WPC डेकिंग प्रणालियों की स्थापना तकनीकों और दृश्य निरंतरता को प्रभावित करते हैं। समन्वित ट्रिम और फैसिया घटक उजागर किनारों और संक्रमण के लिए पेशेवर उपस्थिति और मौसम संरक्षण सुनिश्चित करते हैं। इन आयामी प्रकल्पनाओं को बड़े पैमाने की परियोजनाओं के लिए सामग्री की उपलब्धता और स्थापना दक्षता सुनिश्चित करने के लिए शुरुआती योजना की आवश्यकता होती है।

गुणवत्ता मूल्यांकन और उत्पाद प्रमाणन

उद्योग मानक और परीक्षण प्रोटोकॉल

विश्वसनीय WPC डेकिंग उत्पादों को प्रदर्शन दावों की पुष्टि करने और प्रासंगिक उद्योग मानकों के साथ अनुपालन सुनिश्चित करने के लिए व्यापक परीक्षण से गुजरना पड़ता है। मानकीकृत परीक्षण प्रोटोकॉल विभिन्न पर्यावरणीय स्थितियों के तहत भार क्षमता, फिसलन प्रतिरोध, मौसम प्रतिरोध और आयामी स्थिरता सहित मुख्य प्रदर्शन विशेषताओं का मूल्यांकन करते हैं। थर्ड-पार्टी प्रमाणन उत्पादन बैचों में WPC डेकिंग प्रदर्शन और गुणवत्ता स्थिरता के स्वतंत्र सत्यापन की पेशकश करता है।

गुणवत्ता मूल्यांकन मापदंडों में समान अनुप्रयोगों में निर्माता की प्रतिष्ठा, वारंटी शर्तों और दस्तावेजीकृत प्रदर्शन इतिहास शामिल होना चाहिए। स्थापित निर्माता आमतौर पर परियोजना जीवन चक्र के दौरान व्यापक तकनीकी दस्तावेज़ीकरण, स्थापना दिशानिर्देश और निरंतर तकनीकी सहायता प्रदान करते हैं। ये कारक मांग वाले अनुप्रयोगों में WPC डेकिंग स्थापना की दीर्घकालिक संतुष्टि और प्रदर्शन में महत्वपूर्ण योगदान देते हैं।

वारंटी कवरेज और दीर्घकालिक समर्थन

वाईपीसी डेकिंग प्रदर्शन में निर्माता के विश्वास को दर्शाते हुए व्यापक वारंटी कवरेज संपत्ति मालिकों और ठेकेदारों के लिए महत्वपूर्ण सुरक्षा प्रदान करता है। वारंटी शर्तें आमतौर पर अनुप्रयोगों के आधार पर संरचनात्मक बनावट, रंग स्थिरता और विशिष्ट पर्यावरणीय स्थितियों के प्रति प्रतिरोध को संबोधित करती हैं। वारंटी सीमाओं और रखरखाव आवश्यकताओं को समझने से वाईपीसी डेकिंग प्रणालियों के लिए वास्तविक प्रदर्शन अपेक्षाओं को स्थापित करने में मदद मिलती है।

दीर्घकालिक निर्माता समर्थन में स्थापना सफलता को बढ़ाने वाली प्रतिस्थापन सामग्री, तकनीकी सहायता और उत्पाद अद्यतन की उपलब्धता शामिल है। स्थापित आपूर्ति श्रृंखलाएं भविष्य के विस्तार या मरम्मत की आवश्यकताओं के लिए सुसंगत उत्पाद उपलब्धता सुनिश्चित करती हैं। ये समर्थन कारक विशेष रूप से बड़े पैमाने के सार्वजनिक स्थापनाओं के लिए महत्वपूर्ण साबित होते हैं जहां सामग्री की सुसंगतता और निरंतर उपलब्धता दीर्घकालिक रखरखाव रणनीतियों को प्रभावित करती है।

लागत विश्लेषण और परियोजना अर्थशास्त्र

प्रारंभिक निवेश पर विचार

डब्ल्यूपीसी डेकिंग में पारंपरिक लकड़ी के उत्पादों की तुलना में अधिक प्रारंभिक निवेश की आवश्यकता होती है, लेकिन कम रखरखाव आवश्यकताओं और बढ़ी हुई सेवा आयु के माध्यम से दीर्घकालिक मूल्य प्रदान करती है। लागत विश्लेषण में सामग्री की कीमतों, स्थापना श्रम और डब्ल्यूपीसी डेकिंग स्थापना के लिए आवश्यक किसी भी विशेष उपकरण या फास्टनर्स शामिल होने चाहिए। बड़ी परियोजनाओं के लिए थोक खरीदारी अक्सर महत्वपूर्ण लागत लाभ प्रदान करती है जबकि स्थापना के दौरान सामग्री के एकरूपता को सुनिश्चित करती है।

परियोजना अर्थशास्त्र में स्थल तैयारी आवश्यकताओं, स्थापना उपकरणों के लिए पहुंच और अन्य निर्माण गतिविधियों के साथ समन्वय पर भी विचार किया जाता है। डब्ल्यूपीसी डेकिंग की स्थापना आमतौर पर सुसंगत आयामों और सरलीकृत फास्टनिंग प्रणालियों के कारण पारंपरिक सामग्री की तुलना में तेजी से होती है, जिससे समग्र श्रम लागत कम होती है। ये स्थापना दक्षता उच्च सामग्री लागत की भरपाई करने में सहायता करती हैं जबकि समय-संवेदनशील परियोजनाओं के लिए अनुसूची में लाभ प्रदान करती हैं।

जीवन चक्र लागत लाभ

WPC डेकिंग के लिए स्थापना जीवनकाल के दौरान पारंपरिक सामग्री की तुलना में रखरखाव लागत में बचत एक महत्वपूर्ण आर्थिक लाभ प्रदान करती है। नियमित रूप से ड्रेसिंग, सीलिंग और बोर्ड प्रतिस्थापन की गतिविधियों के समाप्त होने से सामग्री और श्रम लागत दोनों में कमी आती है, साथ ही सुविधा संचालन में बाधा कम होती है। ये बचत समय के साथ संचित होती है, जिससे WPC डेकिंग उन विकल्पों की तुलना में अधिक लागत प्रभावी बन जाती है जिन्हें बार-बार रखरखाव हेतु हस्तक्षेप की आवश्यकता होती है।

पारंपरिक लकड़ी के उत्पादों की तुलना में सुधरी हुई सुरक्षा विशेषताओं और कम आग के खतरे के कारण बीमा और दायित्व पर विचार WPC डेकिंग स्थापना के पक्ष में भी हो सकते हैं। कम रखरखाव आवश्यकताओं से ठेकेदार के दायित्व के जोखिम में कमी आती है और सतह की स्थिर स्थिति सुनिश्चित होती है जो फिसलने और गिरने के जोखिम को कम करती है। ये कारक सीधी सामग्री और स्थापना लागत से परे अतिरिक्त आर्थिक मूल्य प्रदान करते हैं।

सामान्य प्रश्न

वाणिज्यिक अनुप्रयोगों में WPC डेकिंग का आम तौर पर जीवनकाल क्या होता है?

उच्च-गुणवत्ता वाले WPC डेकिंग सिस्टम आमतौर पर उचित ढंग से स्थापित और रखरखाव किए जाने पर व्यावसायिक अनुप्रयोगों में 25-30 वर्षों तक भरोसेमंद सेवा प्रदान करते हैं। इस बढ़ी हुई सेवा आयु आपूर्ति की गुणवत्ता, पर्यावरणीय स्थितियों और अनुशंसित स्थापना प्रथाओं के पालन पर निर्भर करती है। नियमित सफाई और निरीक्षण सेवा जीवन के दौरान WPC डेकिंग के प्रदर्शन को अधिकतम करने में मदद करते हैं।

WPC डेकिंग चरम मौसमी स्थितियों में कैसे प्रदर्शन करती है?

WPC डेकिंग उच्च तापमान, भारी वर्षा और फ्रीज-थॉ चक्र सहित मौसम की विस्तृत परिस्थितियों में उत्कृष्ट प्रदर्शन दर्शाती है। उन्नत सूत्रीकरण दरार, ऐंठन और रंग फीकापन से प्रतिरोध करते हैं, जबकि चरम परिस्थितियों के तहत संरचनात्मक निखरता बनाए रखते हैं। उचित स्थापना तकनीक और उपयुक्त सामग्री चयन कठिन जलवायु में इष्टतम प्रदर्शन सुनिश्चित करते हैं।

WPC डेकिंग स्थापना के लिए किस प्रकार के रखरखाव की आवश्यकता होती है?

डब्बर और मलबे को हटाने के लिए साबुन और पानी के साथ अवधि-अवधि पर सफाई से मुख्य रूप में न्यूनतम रखरखाव की आवश्यकता WPC डेकिंग को होती है। पारंपरिक लकड़ी के उत्पादों के विपरीत, WPC डेकिंग को स्टेनिंग, सीलिंग या क्षतिग्रस्त बोर्डों के नियमित प्रतिस्थापन की आवश्यकता नहीं होती है। उच्च यातायात वाले क्षेत्रों या भारी गंदगी वाली परिस्थितियों वाले वातावरण में आवधिक गहन सफाई की आवश्यकता हो सकती है।

क्या मौजूदा कंक्रीट सतहों के ऊपर WPC डेकिंग की स्थापना की जा सकती है?

उपयुक्त स्लीपर सिस्टम या समायोज्य पेडेस्टल का उपयोग करके मौजूदा कंक्रीट सतहों के ऊपर WPC डेकिंग की सफलतापूर्वक स्थापना की जा सकती है, जो उचित जल निकासी और वेंटिलेशन प्रदान करते हैं। छत अनुप्रयोगों और ऐसे पुनर्निर्माण परियोजनाओं के लिए यह स्थापना विधि विशेष रूप से प्रभावी है, जहां मौजूदा सतहों को हटाना अव्यवहारिक होता है। उचित अधोसंरचना डिज़ाइन पर्याप्त समर्थन सुनिश्चित करता है और नमी से संबंधित समस्याओं को रोकता है जो WPC डेकिंग के प्रदर्शन को प्रभावित कर सकती हैं।